2002 – 2007

overhaul and modernization of domestic and foreign metalworking equipment.

BPK managed to achieve high results in this field of activity, having made a way from the enterprise with single orders to one of the leading companies of the Russian Federation in the field of overhaul and modernization of metalworking equipment.

Over the years, vast experience has been accumulated in the repair and modernization of such groups of machine tools as:

- Lathes with CNC and DRO, including heavy,

- Longitudinal milling machines,

- Machining centers,

- Grinding group,

- CNC Milling machines,

- Horizontal boring machines,

- Lathe-and-boring lathes,

- Heavy and unique equipment (heavy lathes manufactured by KZTS (Kramatorsk), heavy horizontal boring machines NZTS (Novosibirsk), KZTS (Kolomna), IZTS (Ivanovo), Sverdlov, Skoda ( Czech Republic), TOS Wandsdorf (Czech Republic), Maho (Germany), Gildenmeister (Germany), RAMA (Italy), Sharmann (Germany), Oliveti (Italy), Hesketr (Germany), Spinner (Germany) and etc.

This made it possible to form a staff with high competencies in the field of machine tool construction and to develop good industry ties.

2007 – 2009

the beginning of work on the supply of new high-performance metalworking equipment.

Work on the organization of this direction was conducted systematically with a detailed and comprehensive study of the market. Over a relatively short period of time, BPK, becoming one of the Russian dealers of the largest machine tool company SMTCL in China, with an annual capacity of 67,000 units, has made significant progress in promoting this equipment. So, in 2008 and 2009, BPK was officially recognized as the best world dealer by the total sales volume among dealers from 58 countries of the world.

2009 – 2010

exclusive dealership of the leading foreign machine-tool plants.

In connection with the growing demand of Russian enterprises for better equipment, BPK obtained the right to represent the products of the best Taiwanese companies Buffalo Machinery (turning and milling machining centers, 5-axis machining centers, horizontal boring group) in the Russian market, Yu-Shine Precision Machinery (vertical, turning machining centers and lathe-turning machines) and Proth Industrial (grinding equipment).

In 2010, BPK became the exclusive dealer of the Australian company Tecni WaterJet – the world's leading manufacturer of waterjet cutting machines, as well as companies Kunming Machinery (horizontal boring machines) and Averex Automation (horizontal machining centers).

The development of a new direction is developing actively – complex engineering on the principle of "from drawing to detail". The result of this work is ready-made technological processes for the manufacture of parts, including 3D-modeling with the developed control program, selected tools, technological equipment and, ultimately, the production of the detail-representative with the provision of technology to the customer.

2011 – 2013

expansion of customer geography, steady growth in sales dynamics.

BPK demonstrated exceptionally high level of sales dynamics, significantly expanding the client base (the main part of which became permanent), a number of large projects were implemented to provide complex delivery of machine tools to domestic enterprises with detailed engineering work. The geography of supplies has also significantly expanded both in the territory of the entire Russian Federation and at the expense of the neighboring countries: Kazakhstan, Belarus, Kyrgyzstan.

2013

the opening of new own production facilities in the industrial zone "Rybatskoe": BPK-South.

In operation 8 500 sq. m. of own industrial areas, optimized work processes, organized logistics and a unique on the Russian market warehouse program. All this provided great opportunities for the high-quality and prompt delivery of machine tools and their servicing. In the future, the site is upgraded for mechanical processing of the main machine components.

2014

the launch of the project "Machine Tool Building".

Together with the enterprises of Rosatom and the St. Petersburg Polytechnic University Peter the Great, BPK started a project aimed at the production of metal-working machines in the Russian Federation using domestic components and components. The machines are produced under the trade name F.O.R.T. – Force, Opportunities, Russian Technologies. Within the framework of the project, casting and machining of stands, making turrets, tool shops and spindle knots on the territory of Russia are underway, assembly and testing of equipment is underway.

2015 – 2017

Construction of a new research and production complex BPK-North.

In connection with the constant growth and development of the enterprise, the construction of the second site of the company – BPK-North has begun. The opening of a joint design office with SPbPU for further work on the production of metalworking machines F.O.R.T., as well as for "for the future" – research in the field of additive technologies and powder materials".

2017

launch of the second production site of the company.

In the current year, the grand opening of the BPK-North research and production complex took place. On an area of 22 000 square meters. m. are located:

- The modern design bureau – together with SPbPU.

- Plot of promising developments. In October 2017, a hybrid additive installation and new equipment for production automation were presented and patented.

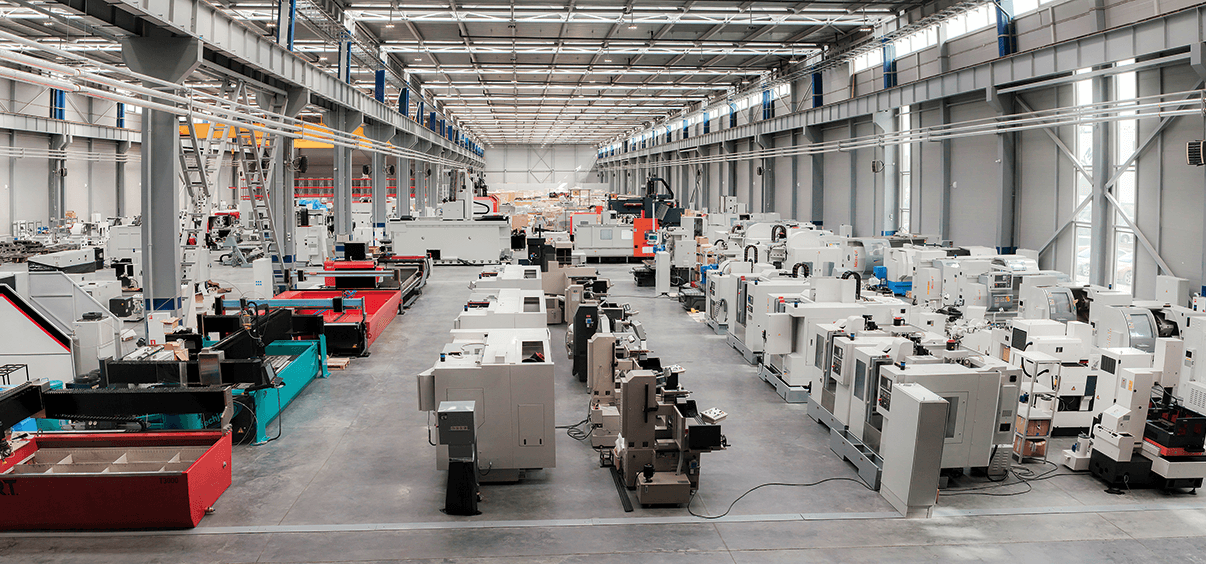

- Metalworking equipment warehouse – more than 200 machines in stock:

- lathes;

- Milling machines;

- 5-axis high-speed machining centers;

- portal 5 axial machine tools;

- Horizontal boring machines;

- portal-milling machines;

- Lathe-boring lathes;

- hydroabrasive and plasma cutting plants;

- Grinding machines;

- electro-erosion equipment.

- A new showroom, where more than 50 models of equipment are presented. All machines are connected and ready to work.

- Assembly site of F.O.R.T machines.